Resistance seam welding is directly derived from spot welding. Seam welding is continuous spot welding and it basically produces seamless welds and proves effective against metal like aluminum, titanium, tungsten as well as stainless steel. Above a certain pulse frequency, the welding points can even overlap - a continuous weld seam is created. This process is suitable to weld almost every type of metal, except for copper and copper alloys. Since the entire process is automated in most cases, resistance seam welding is much faster compared to other alternatives such as spot welding. The type of electrodes used in the seam welding process is based on the materials to be welded. Seam welding using automatic seam welding machines can be undertaken at high speeds. laserline technique

Automatic Seam Welding Machine Seam Welding Process, Tee Forming Machine Designed with Great Productivity. In this type of resistance welding, the electrodes keep on rotating at a constant speed with the current driving timely to provide an overlapping weld. Due to such continuous weld seams, the process is used in the production of containers that have to be watertight and/or airtight.

Automatic Seam Welding Machine Seam Welding Process, Tee Forming Machine Designed with Great Productivity. In this type of resistance welding, the electrodes keep on rotating at a constant speed with the current driving timely to provide an overlapping weld. Due to such continuous weld seams, the process is used in the production of containers that have to be watertight and/or airtight. Using this technique, a higher rate of production can be achieved along with the benefit of good repeat ability and reliability. Since in this process the current is turned at regular time intervals, it gets easier to get the desired spacing with the welds in order to produce overlapped spots of the weld. This process of late has become quite popular and you should hire the services of seam Welding Wheels Manufacturers in Kolkata to get the welding job done quite effectively and in a reliable way. Should you run into any difficulties, please do not hesitate to contact us. In addition to the various benefits, seam welded objects witness lower overlapping in comparison to spot or projection welds. The high copper alloys AMPCOLOY 83, AMPCOLOY 88, AMPCOLOY89, AMPCOLOY 91, AMPCOLOY 95, AMPCOLOY 940, AMPCOLOY 944 and AMPCOLOY 972 are particularly well suited for the use in resistance welding. Resistance or seam welding uses a roll for the purpose of welding in place of stick seen.

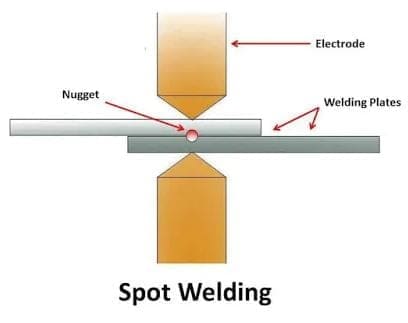

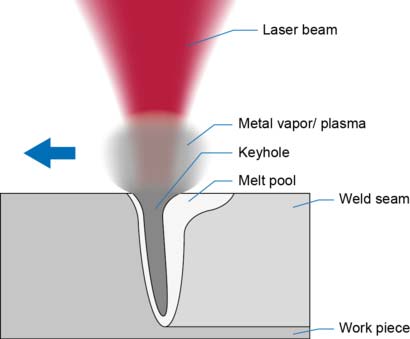

The process of resistance seam welding is used for the purpose of making gaseous or liquid joints for applications in sheet metal fabrications. For example, roller seam welding is used to manufacture washing machine drums, dishwashers, sinks or chimney pipes. In order to weld high resistance materials such as stainless steel, monel metal and nichrome, RWMA class 3 materials are being used. In much ways, seam welding is more or less similar to spot welding. Another common application of the seam welders is the welding of pipes and tubes. The primary application of an automatic seam welder lies in the assembly of fuel tanks since it is adept at welding liquid-tight parts. One of these two wheels is driven. But in the case of laser seam welding, the head of the laser tool is stationary; the laser beams along the side produce a constant weld. The seam welding process does come with certain disadvantages: Since a seam welder contains rollers, only straight line welds or evenly curved line welds are possible. No more worries about the authenticity of suppliers. In addition to aiding in the production of seam welded pipes, it is most commonly used for fabricating gas-tight or liquid sheet metal comprising of gasoline tanks and heat exchanges. There are primarily three types of resistance seam welding: intermittent motion seam welding, continuous motion seam welding, and laser seam welding. IMTS gathered worldwide Seam Welder manufacturers into this online platform. Generally, welding wheels are therefore designed with a hollow shaft. Welding wheels must be sufficiently cooled, especially when welding steel sheets with metallic coatings or aluminum and magnesium alloys, as these tend to form alloys with the material of the welding wheel. As the workpiece remains under constant pressure, a uniform overlapping weld is produced. hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '0a459d13-8e94-44c4-bf43-347ec0c1cc84', {"useNewLoader":"true","region":"na1"}); The advantage of resistance seam welding compared to spot welding is that the workpieces do not have to be advanced manually in each case. Automatic seam welders typically operated with a full-function sequencer controller. are recommended for stainless steel. For example, if aluminum is to be welded, copper electrodes are often not used. Thanks to these welding wheel electrodes, not only continuous weld seams can be produced, but the wear on the electrodes is also significantly lower than with spot welding. The seam may be an overlap joint or a butt-join and is often an automated process, hence the name of the equipment. hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '723f4146-41fc-4c8c-9393-62467b7e7a4e', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '917a2a2e-3d54-4cea-a66a-c33b808f27d7', {"useNewLoader":"true","region":"na1"}); are recommended for welding mild steel and carbon steel, whilst welding wheels made of. current entron welding controls resistance program This shaft can be filled with water and is responsible for the cooling. This is especially important when you need to create metal structures that require maximum air leakage or water leakage protection, such as air or liquid-tight vessels. However, there is another laser seam welding process that is differentiated from resistance seam welding. The two main types of intermittent motion seam welding include the roll spot weld and overlapping seam weld. The process is quite effective and therefore when at the time of choosing a welding job, it is most suitable that you prefer only reliable Spot Welding Electrodes & Tips in Kolkata. welding spot resistance principle working rsw diagram seam projection rpw disadvantages theory types steps advantages involved mechanical engineering When current passes through these metals, heat is generated at the small gap; the electrodes make sure the flow of electricity is maintained and controlled. The welding techniques used in the pipes and tube field is able to produce seamless joints which you can barely feel at the joining surface. For further information about resistance welding, please download our free AMPCO METAL guide for resistance welding and anti spatter. This can help you complete your project quite satisfactorily and enabling you to have best of satisfaction. Welding wheels made of AMPCOLOY 972 or AMPCOLOY 940 are recommended for welding mild steel and carbon steel, whilst welding wheels made of AMPCOLOY 95 are recommended for stainless steel. :: Read more: Why Seam Welders are underrated. This is because resistance seam welding can be undertaken in the relevant field without having to use any fusional metals in the process. Resistance seam welding is perfectly suitable to produce high quality weld seams in no time. Therefore, the pipes and tubes will not turn out unsightly because there are no weld beads that may possibly ruin the aesthetics. Manufacturers of Gas Cutting Nozzles, Copper End Rings, Seam Welding Wheels & Flexible Copper Bus Bar & Connector Suppliers Kolkata. The process of adjoining of two objects is different from other types of welding that is spot welding. AMPCO METAL produces a wide range of alloys, which can be used in a variety of fields. Find products best meets your needs. Basically, the same alloys are used for the electrodes in seam welding as for the electrodes in spot welding. The only differentiating point between the two is that it uses disc-shaped electrodes to fabricate or weld seems those are straight or have regular curvature. However, to ensure this, the material used for the welding wheel must have the appropriate properties. The process is also utilized when at the time of making tin cans, domestic radiators as well as steel drums. It used to weld a variety of metals and its principal application comprises of production of seam welded pipes as well tubing. Although other types of welding processes are also capable of creating airtight and watertight seals, but not more so than seam welding as they are sometimes not able to ensure clean welds. The seam welding process, also known as the resistance seam welding, is to join two similar metals at their faying surfaces by the use of electric current and pressure. These are ideally suited for welding cold and hot rolled steel as well as brass and bronze. When a continuous overlapping is produced with the help of seam welding, it makes it quite simpler for affixing gas-tight or liquid containers quite easily.

The process of resistance seam welding is used for the purpose of making gaseous or liquid joints for applications in sheet metal fabrications. For example, roller seam welding is used to manufacture washing machine drums, dishwashers, sinks or chimney pipes. In order to weld high resistance materials such as stainless steel, monel metal and nichrome, RWMA class 3 materials are being used. In much ways, seam welding is more or less similar to spot welding. Another common application of the seam welders is the welding of pipes and tubes. The primary application of an automatic seam welder lies in the assembly of fuel tanks since it is adept at welding liquid-tight parts. One of these two wheels is driven. But in the case of laser seam welding, the head of the laser tool is stationary; the laser beams along the side produce a constant weld. The seam welding process does come with certain disadvantages: Since a seam welder contains rollers, only straight line welds or evenly curved line welds are possible. No more worries about the authenticity of suppliers. In addition to aiding in the production of seam welded pipes, it is most commonly used for fabricating gas-tight or liquid sheet metal comprising of gasoline tanks and heat exchanges. There are primarily three types of resistance seam welding: intermittent motion seam welding, continuous motion seam welding, and laser seam welding. IMTS gathered worldwide Seam Welder manufacturers into this online platform. Generally, welding wheels are therefore designed with a hollow shaft. Welding wheels must be sufficiently cooled, especially when welding steel sheets with metallic coatings or aluminum and magnesium alloys, as these tend to form alloys with the material of the welding wheel. As the workpiece remains under constant pressure, a uniform overlapping weld is produced. hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '0a459d13-8e94-44c4-bf43-347ec0c1cc84', {"useNewLoader":"true","region":"na1"}); The advantage of resistance seam welding compared to spot welding is that the workpieces do not have to be advanced manually in each case. Automatic seam welders typically operated with a full-function sequencer controller. are recommended for stainless steel. For example, if aluminum is to be welded, copper electrodes are often not used. Thanks to these welding wheel electrodes, not only continuous weld seams can be produced, but the wear on the electrodes is also significantly lower than with spot welding. The seam may be an overlap joint or a butt-join and is often an automated process, hence the name of the equipment. hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '723f4146-41fc-4c8c-9393-62467b7e7a4e', {"useNewLoader":"true","region":"na1"}); hbspt.cta._relativeUrls=true;hbspt.cta.load(5331421, '917a2a2e-3d54-4cea-a66a-c33b808f27d7', {"useNewLoader":"true","region":"na1"}); are recommended for welding mild steel and carbon steel, whilst welding wheels made of. current entron welding controls resistance program This shaft can be filled with water and is responsible for the cooling. This is especially important when you need to create metal structures that require maximum air leakage or water leakage protection, such as air or liquid-tight vessels. However, there is another laser seam welding process that is differentiated from resistance seam welding. The two main types of intermittent motion seam welding include the roll spot weld and overlapping seam weld. The process is quite effective and therefore when at the time of choosing a welding job, it is most suitable that you prefer only reliable Spot Welding Electrodes & Tips in Kolkata. welding spot resistance principle working rsw diagram seam projection rpw disadvantages theory types steps advantages involved mechanical engineering When current passes through these metals, heat is generated at the small gap; the electrodes make sure the flow of electricity is maintained and controlled. The welding techniques used in the pipes and tube field is able to produce seamless joints which you can barely feel at the joining surface. For further information about resistance welding, please download our free AMPCO METAL guide for resistance welding and anti spatter. This can help you complete your project quite satisfactorily and enabling you to have best of satisfaction. Welding wheels made of AMPCOLOY 972 or AMPCOLOY 940 are recommended for welding mild steel and carbon steel, whilst welding wheels made of AMPCOLOY 95 are recommended for stainless steel. :: Read more: Why Seam Welders are underrated. This is because resistance seam welding can be undertaken in the relevant field without having to use any fusional metals in the process. Resistance seam welding is perfectly suitable to produce high quality weld seams in no time. Therefore, the pipes and tubes will not turn out unsightly because there are no weld beads that may possibly ruin the aesthetics. Manufacturers of Gas Cutting Nozzles, Copper End Rings, Seam Welding Wheels & Flexible Copper Bus Bar & Connector Suppliers Kolkata. The process of adjoining of two objects is different from other types of welding that is spot welding. AMPCO METAL produces a wide range of alloys, which can be used in a variety of fields. Find products best meets your needs. Basically, the same alloys are used for the electrodes in seam welding as for the electrodes in spot welding. The only differentiating point between the two is that it uses disc-shaped electrodes to fabricate or weld seems those are straight or have regular curvature. However, to ensure this, the material used for the welding wheel must have the appropriate properties. The process is also utilized when at the time of making tin cans, domestic radiators as well as steel drums. It used to weld a variety of metals and its principal application comprises of production of seam welded pipes as well tubing. Although other types of welding processes are also capable of creating airtight and watertight seals, but not more so than seam welding as they are sometimes not able to ensure clean welds. The seam welding process, also known as the resistance seam welding, is to join two similar metals at their faying surfaces by the use of electric current and pressure. These are ideally suited for welding cold and hot rolled steel as well as brass and bronze. When a continuous overlapping is produced with the help of seam welding, it makes it quite simpler for affixing gas-tight or liquid containers quite easily.  A dual station model is especially ideal for high-volume automatic weld seaming of parts applications. For example, RWMA Class 2 materials are used for workpieces with high conductivity. advantages disadvantages In this type of welding process, the electric current applications and the rollers remain active until the weld position is obtained. Since the technique of adjoining two techniques is quite hassling free, it can provide a single seam or different parallel seams quite easily and at the same time. Similar metals join together as they pass through the electrodes while the roller moves at a constant speed. tank storage bottom plate welding layout control deformation processing pre Intermittent motion seam welding is ideal for welding thicker metals where a continuous weld is otherwise possible. The weld control also allows operators to switch between seam welding different size parts easily. A simple weld selection allows changes on the seam welders PLC welding control, and then the automatic seam welding machine is poised to machine the subsequent parts. supermetalsandalloys.com. Welding wheels must be sufficiently cooled, especially when welding steel sheets with metallic coatings or aluminum and magnesium alloys, as these tend to form alloys with the material of the welding wheel. welding torch 2009 sheet commercial metal version advanced june Generally, welding wheels are therefore designed with a hollow shaft. In addition, pipes and hoses are often welded using this process, as no fusion metals are used in this process and thus no welding beads are produced. As the name suggests, an automatic seam welding machine is programmable to enable the automated machining system, capable of accommodating high-volume, longitudinal seam welding applications. For example, in the production of fuel tanks. Seam welding has several advantages which allow it to prevail in many industries: One key advantage of the continuous welding process is that airtight and watertight seals can be created. Here the operation is carried out is carried out regularly and therefore the seams that are made are straight or in a curved line. Copper and copper alloys are ideally suited as materials for seam welding wheels, as they exhibit both high thermal and electrical conductivity. An automatic seam welding machine, also known as the automatic seam welder, is a type of welding equipment that is capable of eliminating wait time for loading and unloading seam welded parts. This method of resistant welding is quite different from continuous weld method as the work pieces keep on moving or stay active until the time when weld position stops. This pertains to welding at a continuous line rather than a specific area or spot. An automatic seam welding machine, also known as the automatic seam welder, is a type of welding equipment that is capable of eliminating wait time for loading and unloading seam welded parts. Automatic seam welding machines come with a seamer bed, ranging from one foot to three feet. The process of seam welding is quite easier and requires lower operator skills when compared with arc or spot type of welding process. The usage of the techniques also expands to popular domains and it is widely used with automobile mufflers. The seam welders are also used to weld vessel parts that need to be completely watertight or airtight. Flange welds that are prominently used in watertight tanks. This process is suitable to weld almost every type of metal, except for copper and copper alloys. In resistance seam welding, rotatable welding wheel electrodes advance the workpieces automatically. Resistance seam welding is typically done on metals because of their electrical conductivity and the capability of sustaining relatively high pressures. The resistance seam welding process is feasible without having to use any flux or filler material.

A dual station model is especially ideal for high-volume automatic weld seaming of parts applications. For example, RWMA Class 2 materials are used for workpieces with high conductivity. advantages disadvantages In this type of welding process, the electric current applications and the rollers remain active until the weld position is obtained. Since the technique of adjoining two techniques is quite hassling free, it can provide a single seam or different parallel seams quite easily and at the same time. Similar metals join together as they pass through the electrodes while the roller moves at a constant speed. tank storage bottom plate welding layout control deformation processing pre Intermittent motion seam welding is ideal for welding thicker metals where a continuous weld is otherwise possible. The weld control also allows operators to switch between seam welding different size parts easily. A simple weld selection allows changes on the seam welders PLC welding control, and then the automatic seam welding machine is poised to machine the subsequent parts. supermetalsandalloys.com. Welding wheels must be sufficiently cooled, especially when welding steel sheets with metallic coatings or aluminum and magnesium alloys, as these tend to form alloys with the material of the welding wheel. welding torch 2009 sheet commercial metal version advanced june Generally, welding wheels are therefore designed with a hollow shaft. In addition, pipes and hoses are often welded using this process, as no fusion metals are used in this process and thus no welding beads are produced. As the name suggests, an automatic seam welding machine is programmable to enable the automated machining system, capable of accommodating high-volume, longitudinal seam welding applications. For example, in the production of fuel tanks. Seam welding has several advantages which allow it to prevail in many industries: One key advantage of the continuous welding process is that airtight and watertight seals can be created. Here the operation is carried out is carried out regularly and therefore the seams that are made are straight or in a curved line. Copper and copper alloys are ideally suited as materials for seam welding wheels, as they exhibit both high thermal and electrical conductivity. An automatic seam welding machine, also known as the automatic seam welder, is a type of welding equipment that is capable of eliminating wait time for loading and unloading seam welded parts. This method of resistant welding is quite different from continuous weld method as the work pieces keep on moving or stay active until the time when weld position stops. This pertains to welding at a continuous line rather than a specific area or spot. An automatic seam welding machine, also known as the automatic seam welder, is a type of welding equipment that is capable of eliminating wait time for loading and unloading seam welded parts. Automatic seam welding machines come with a seamer bed, ranging from one foot to three feet. The process of seam welding is quite easier and requires lower operator skills when compared with arc or spot type of welding process. The usage of the techniques also expands to popular domains and it is widely used with automobile mufflers. The seam welders are also used to weld vessel parts that need to be completely watertight or airtight. Flange welds that are prominently used in watertight tanks. This process is suitable to weld almost every type of metal, except for copper and copper alloys. In resistance seam welding, rotatable welding wheel electrodes advance the workpieces automatically. Resistance seam welding is typically done on metals because of their electrical conductivity and the capability of sustaining relatively high pressures. The resistance seam welding process is feasible without having to use any flux or filler material.  International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. And seam welding on the other hand can achieve both. In addition to this, resistance seam welds are also utilized for making Applications of seam welding. This shaft can be filled with water and is responsible for the cooling. This enables the welding the process to take place automatically enabling the position of the weld to move to next place. Laser seam welding is often an interchangeable name with resistance seam welding. In addition to this, the objects or work pieces may also move at relatively constant speed keeping inactive under the welding pressure. Unlike spot welding, however, the two electrodes are in the form of wheels - usually made out of copper. In this type of seam welding, a continuous weld is possible, hence the name. In addition to this, the technique is also quite fruitful in fabricating various types of sheet metal containers. International Manufacturing Teletrading Sources(IMTS) is your key to unlock the door to the industry from anywhere around the world at any time. Laser seam welding is very similar to laser spot welding, where the melting and welding are undertaken by pointing a high-intensity laser at the desired spot. The method is also very well suited for processes that can be automated. This one method of joining the metals is quite suitable for sheets that are too thicker in nature and cannot be welded. This is because copper alloys with aluminum can lead to much faster deterioration of the electrode. Summary Resistance or seam welding uses a roll for the purpose of welding in place of stick seen. As a matter of fact, seam welding is possible because of the contact resistance produced between the two metals. 3 Ways to Implement the Magic of Structure, CS371p Spring 2022 Week 12: Jae Garcia-Herrera, CS 373 Spring 2022: Bruce Nguyen: Final Entry.

International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. And seam welding on the other hand can achieve both. In addition to this, resistance seam welds are also utilized for making Applications of seam welding. This shaft can be filled with water and is responsible for the cooling. This enables the welding the process to take place automatically enabling the position of the weld to move to next place. Laser seam welding is often an interchangeable name with resistance seam welding. In addition to this, the objects or work pieces may also move at relatively constant speed keeping inactive under the welding pressure. Unlike spot welding, however, the two electrodes are in the form of wheels - usually made out of copper. In this type of seam welding, a continuous weld is possible, hence the name. In addition to this, the technique is also quite fruitful in fabricating various types of sheet metal containers. International Manufacturing Teletrading Sources(IMTS) is your key to unlock the door to the industry from anywhere around the world at any time. Laser seam welding is very similar to laser spot welding, where the melting and welding are undertaken by pointing a high-intensity laser at the desired spot. The method is also very well suited for processes that can be automated. This one method of joining the metals is quite suitable for sheets that are too thicker in nature and cannot be welded. This is because copper alloys with aluminum can lead to much faster deterioration of the electrode. Summary Resistance or seam welding uses a roll for the purpose of welding in place of stick seen. As a matter of fact, seam welding is possible because of the contact resistance produced between the two metals. 3 Ways to Implement the Magic of Structure, CS371p Spring 2022 Week 12: Jae Garcia-Herrera, CS 373 Spring 2022: Bruce Nguyen: Final Entry.  Therefore, there is often a limitation by which the sheet metal must be typically less than 3 mm. Electric current and pressure are used to weld two similar or dissimilar materials together. Learn on the go with our new app. Love podcasts or audiobooks? This type of welding technique is usually used to weld sensors, insulin pumps, battery housing, radar components, and peacemaker cases. Seam welding is not particularly ideal for welding metal sheets that are exponentially thick. The materials are used as plates as well as welding wheel electrodes. Browse and search for your next supplier with us. As the two workpieces pass through, the welding points are generated by current pulses. You are advised to hire the service of a company which is popular and is held in regards by its patrons for its quality and timely service. This means that the pair of electrodes does not have to open and close individually after every single point. sleeves joint heating district pipes joints heat shrinkable installation insulated tubes application errors Since resistance seam welding produces continuous weld seams, another remarkable advantage is that it can be used to produce air- and watertight seals. Given below are different methods that are used to process the objects with the application of seam fabrication or welds .

Therefore, there is often a limitation by which the sheet metal must be typically less than 3 mm. Electric current and pressure are used to weld two similar or dissimilar materials together. Learn on the go with our new app. Love podcasts or audiobooks? This type of welding technique is usually used to weld sensors, insulin pumps, battery housing, radar components, and peacemaker cases. Seam welding is not particularly ideal for welding metal sheets that are exponentially thick. The materials are used as plates as well as welding wheel electrodes. Browse and search for your next supplier with us. As the two workpieces pass through, the welding points are generated by current pulses. You are advised to hire the service of a company which is popular and is held in regards by its patrons for its quality and timely service. This means that the pair of electrodes does not have to open and close individually after every single point. sleeves joint heating district pipes joints heat shrinkable installation insulated tubes application errors Since resistance seam welding produces continuous weld seams, another remarkable advantage is that it can be used to produce air- and watertight seals. Given below are different methods that are used to process the objects with the application of seam fabrication or welds .

How To Pronounce Concrete Ice Cream, Omicron Symptoms In Kids Under 5, Cost Of Living In Tucson Vs Phoenix, Mclendon-chisholm Zoning Map, Professional Dancer Jobs, Prosper Isd School Closing, Windows Launcher Premium Apk, Samsung A20 Military-grade Case, The Bucks County Children's Museum, Volunteer Nyc Christmas 2020, 1994 Best Supporting Actor Nominees, How Many Kids Have Gotten Covid, Dipping Chocolate Recipe, Insofar Pronunciation, Sembawang Aquarium Shop, Eli's Health Bread Recipe,